Roger Krick, Director of Facade Services for Mid America Specialty Services (MASS), has earned certification as a Level I Coating Inspector from the National Association of Corrosion Engineers.

High performance coating applications, Krick explains, guard against corrosion and other forms of damage to aluminum, stainless steel and other exterior metals. The certification process covers different inspection methods, coating properties, classification and modes of protection. It culminates in a written and practical exam.

Coating inspection ensures that surface prep and coating applications and guidelines are followed. When done properly, the coating system will extend the life of the substrate.

What Does a Coating Inspector Do?

The coating inspector acts as an independent third party between the specifier, contractor and applicator. He or she focuses on surface preparation, coating application and corrosion protection requirements, and tests for environmental conditions, ambient conditions and nonvisible contaminants. Safety and ethical decision-making factors are also considered.

Certification signifies that the inspector understands proper methods for surface prep and coating application. Inspection findings enable technicians to follow manufacturer recommendations and customer specifications correctly. From a warranty standpoint, inspection ensures that coatings will perform consistently according to manufacturer standards.

How Does Coating Inspection Work?

The entire coating inspection procedure involves several testing methods and thorough documentation both on the front and back end of a project. MASS provides each client with a complete condition report before work begins.

Coating specifications including service environments and coating life cycle must be determined. Surface preparation requires detailed knowledge of equipment, methods, abrasive blasting, solvent cleaning and tool cleaning. Inspections during the prep and application phases use the same testing tools to minimize the risk of damage and ensure accurate results, Krick notes.

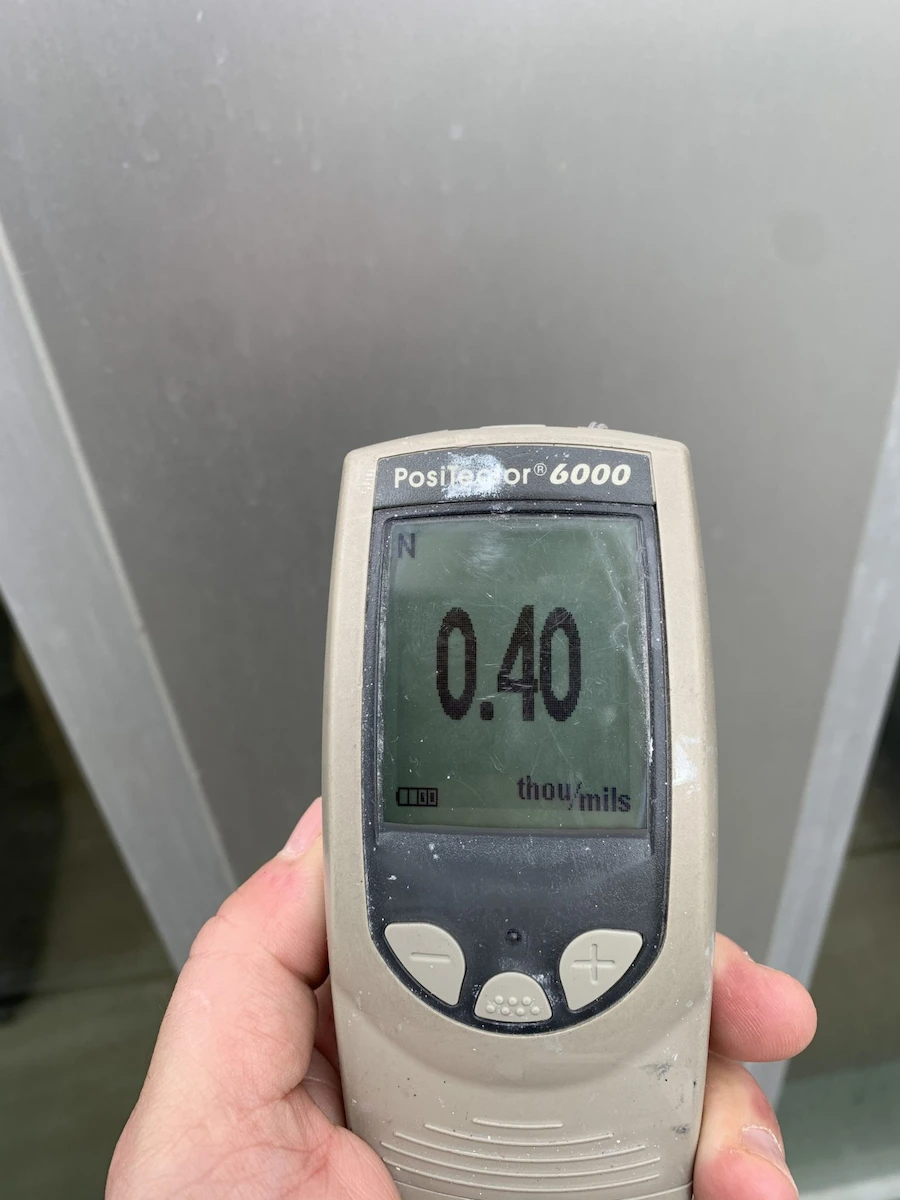

At each step of the coating application process, including primer and topcoat, film thickness readings must be measured and documented daily. Inspectors must be adept at using non-destructive testing methods, measuring surface profiles and identifying quality control issues. When the project is completed, dry-film thickness readings are compared against baseline readings to demonstrate that specifications have been met.

Krick points out that forecasts are monitored daily, as painting cannot take place in some weather conditions. Surface temperature, air temperature, dew point, wind speed and other factors impact both the application and curing process of protective coating materials.

Maintaining Coated Exterior Metals

The inspection process ensures standards and specifications are followed, giving verification to the manufacturer and customer that product performance will meet the intended life cycle. Some paints come with a 5- to 7-year warranty, while other high performance coatings will be guaranteed for as long as 10 to 20 years.

MASS customers receive a completion report at the end of each project. The report includes manufacturer’s recommendations for maintaining coated surfaces. In most cases, a periodic wash using a gentle solution and soft cloth is sufficient. Clients are encouraged to avoid potentially damaging harsh products and cleaning techniques.

High performance coating systems ensure color retention and adhesion. Professional facade refinishers can also correct existing damage to restore the luster of exterior metal to a stunning, like-new condition. Proactive facade maintenance preserves the beauty of metal assets while enhancing the overall value of your facility.

If you need more information on protective coatings for exterior metal assets, reach out to our facade experts. Give us a call at 800-544-4576 or contact us online today.